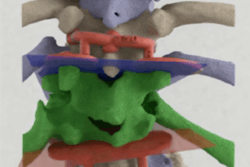

Researchers from Austria have set out to create 3D-printed organs using materials that resemble the properties of real tissue.

In recent years, clinicians have been using 3D-printed anatomical models to plan and simulate complex surgeries. One of the main drawbacks of this practice is that the models lack the realistic characteristics of biological tissue, noted lead investigator Dieter Pahr, PhD, from Karl Landsteiner University of Health Sciences in Krems.

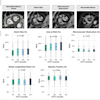

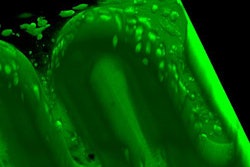

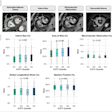

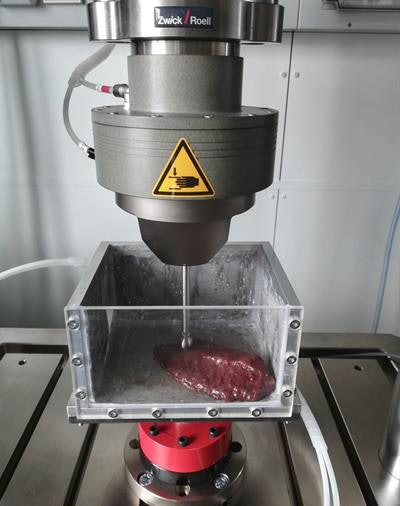

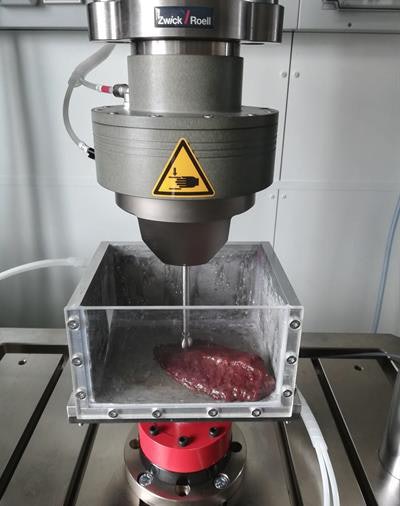

Identifying the biomechanical properties of organ tissue for 3D bioprinting. Image courtesy of Dieter Pahr, PhD, from Karl Landsteiner University of Health Sciences in Krems.

Identifying the biomechanical properties of organ tissue for 3D bioprinting. Image courtesy of Dieter Pahr, PhD, from Karl Landsteiner University of Health Sciences in Krems.Hoping to improve the value of 3D-printed models, Pahr and colleagues have begun a new research project at their institution that aims to identify the biomechanical properties of actual organ tissue and then use this information to determine the best-suited biomaterials for making lifelike 3D-printed organs.

Furthermore, they plan to develop a computer model that can predict the mechanical qualities of 3D-printed biological tissues based on their microstructures and their material composition. Ultimately, the group hopes that by inputting the properties of a particular type of tissue into a computer program, they will be able to create realistic 3D-printed organs.

This work can bolster the field of medical 3D printing and may eventually "open the door for highly customized and realistic tissue and organ models for medical use," the researchers noted.