Researchers from a top London facility have developed a 3D printing technique to produce structures that mimic the properties of the softest tissues in the body. These structures may serve as templates for tissue regeneration, according to a study published in Scientific Reports.

Current efforts in 3D bioprinting include regenerating tissue and creating full human organs. A major challenge in this field is replicating the extreme softness and hollow shape of delicate organs such as the brain and lungs.

Meeting this obstacle head-on, a group from Imperial College London has developed a way to fabricate complex structures that, unlike structures made using the standard method of cast molding, match the stiffness and geometry of these soft tissues.

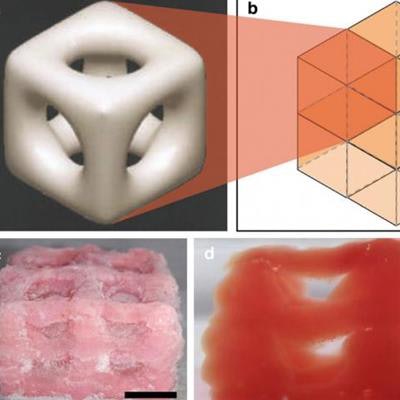

The 3D-printed scaffold unit as (a) a cylindrical pore microstructure, (b) a layout of the 8-unit cell, (c) a thawed, 3D-printed 8-unit structure in isometric view, and (d) a frozen, 3D-printed 8-unit structure in side view. Scale bars: (c) 10 mm and (d) 5 mm. Images courtesy of Imperial College London.

The 3D-printed scaffold unit as (a) a cylindrical pore microstructure, (b) a layout of the 8-unit cell, (c) a thawed, 3D-printed 8-unit structure in isometric view, and (d) a frozen, 3D-printed 8-unit structure in side view. Scale bars: (c) 10 mm and (d) 5 mm. Images courtesy of Imperial College London.The team began by modifying a 3D printer (Ultimaker 2+, Ultimaker) to print soft structures using a hydrogel ink (Phytagel, Sigma-Aldrich) mixed with polyvinyl alcohol that maintains the same stiffness as soft tissues. Then they connected a thermal conductive bath loaded with solid carbon dioxide (dry ice) and isopropanol to the steel plate onto which the 3D printer extruded the ink. With this setup, the ink cooled as it touched the 3D printing platform and took its new shape.

"Cryogenics is the novel aspect of this technology -- it uses the phase change between liquid and solid to trigger polymerization and create super soft objects that can hold their shape," principal investigator Dr. Antonio Elia Forte said in a statement. "This means the technology has a wide variety of possible uses."

This cryogenic 3D printing technique allowed the researchers to 3D print a porous, two-layered cube with a height of 10 mm. When thawed, the structure's material mirrored the stiffness of soft tissues (0.49 ± 0.04 kPa) and was able to retain water within each one of its eight cells. The result led the researchers to believe these 3D-printed cubes could serve as scaffolds on which damaged tissues could regrow (Sci Rep, 24 November 2017).

To test the viability of the 3D-printed cube in aiding tissue regeneration, the group coated it with collagen gel and exposed it to a live culture of dermal fibroblast cells for 72 hours. They found more than 97% of the live cells remained on the cube, which suggested successful attachment and survival.

"At the moment we have created structures a few centimeters in size, but ideally we'd like to create a replica of a whole organ using this technique," first author Dr. Zhengchu Tan said.

A notable limitation of the approach was the occasional unevenness of the 3D-printed cubes; there was no way to smooth each layer because the ink froze immediately when deposited. Once the consistency of the 3D printing has been improved, scientists could use the cryogenic 3D printing technique to fabricate very soft, complex, 3D-printed scaffolds for tissue engineering purposes, according to the authors. There might even be potential in regenerating neuronal cells on these 3D-printed cubes.

"The use of the composite hydrogel as an ink in cryogenic 3D printing opens the doors to many applications that have yet to be explored due to the inability to fabricate super soft materials that mimic the stiffness of brain, lung, and other human tissues," they wrote. "[The technology could be used in applications] from soft-tissue phantoms for surgical training and simulations to mechanobiology and tissue engineering."