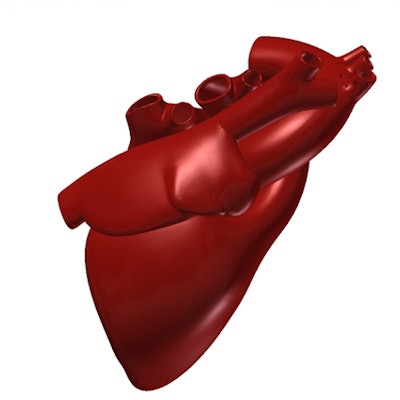

A Swiss group has developed a soft 3D-printed silicone heart that beats almost like a human heart. The technique, which uses CT images of a real patient to create a computer-aided design (CAD) model in 3D, could in the future provide tailor-made, soft artificial hearts made of silicone that fit the anatomy specific to each patient, with potentially lower risk of complications after implantation.

The researchers from the Functional Materials Laboratory at the Swiss Federal Institute of Technology in Zurich (ETHZ) wanted to mimic the natural model as closely as possible so that it looked and behaved like a real heart, according to Nicholas Cohrs and Xavier Kohll, project leaders for the first and second prototypes.

To develop the initial prototype, the group took a CAD file created from a CT scan of a real healthy human heart, and using Siemens Healthineers NX8.5 CAD software, they designed the outer form of the silicone heart to produce a 3D mold printed in acrylonitrile butadiene styrene. Silicone was then poured into the mold to produce the artificial heart using a lost-wax casting technique.

CT imaging will facilitate tailored heart replacements in the future, Xavier Kohll said.

CT imaging will facilitate tailored heart replacements in the future, Xavier Kohll said."The process will allow us to customize hearts patient by patient in line with their needs through creating 3D models based on CT data about their biological hearts and heart space in the chest. This is something we will examine at a later stage," Kohll told AuntMinnieEurope.com, adding that the development and testing of ETHZ's silicone total artificial heart is a subproject of the University of Zurich's "Zurich Heart Project."

The goal is to deliver patient-specific artificial hearts.

"With 3D printers, it will be easy to change the artificial heart to make it fit each patient. This is definitely a big advantage of our technique and a huge step forward toward personalized artificial heart replacements," Cohrs noted.

Around 26 million people worldwide suffer from heart failure, according to a paper co-authored by the group about the silicone heart and published online by Artificial Organs on 10 July.

Nicholas Cohrs.

Nicholas Cohrs.Artificial blood pumps, or ventricular assist devices (VADs), can serve as a temporary measure until a patient receives a donor heart or his or her own heart recovers. However, donor hearts are in short supply, while adverse events post VAD implantation, such as hemolysis and thrombosis, as well as infections, pose a risk to patient health and quality of life. Furthermore, all existing VADs and total artificial hearts (TAHs) are thrombogenic when in contact with blood, meaning the risk of thromboembolism and the need for anticoagulation therapy with the inherent risk of bleeding complications represent major challenges of current VAD and TAH systems. For this reason, researchers are now looking to alternative technologies such as that behind the silicone heart design, to find solutions for patients.

Design and function

The pneumatically driven silicone heart weighs 390 grams and has a volume of 679 cm3. The chambers were designed without atriums, but with a left ventricle and a right ventricle of 144 cm³ and 83 cm³ respectively. The 24 mm-diameter inflow to the heart was placed at the back of the silicone device, while the 30 mm diameter outflow from the ventricles is in the anatomically correct position to facilitate connection to the aorta and the pulmonary artery.

The Zurich device looks and moves like a real heart, but work is now needed to increase its duration.

The Zurich device looks and moves like a real heart, but work is now needed to increase its duration.The right and left ventricles are separated by an expansion chamber, which is inflated and deflated by pressurized air. Instead of muscle contraction as seen in a biological human heart, it is this pressurized air that is required to pump fluid from both chambers.

"We've worked with CAD software before to develop different types of soft pumps. It was the next logical step to develop a soft pump that mimics the action of the heart," Kohll noted. "The proof-of-concept prototype can last for 3000 beats -- that's between 30 to 45 minutes depending on heart rate."

The soft silicone total artificial heart -- with its capacity for patient-specification, as compared with traditional thrombogenic blood pumps -- could be the heart replacement method of the future.

The soft silicone total artificial heart -- with its capacity for patient-specification, as compared with traditional thrombogenic blood pumps -- could be the heart replacement method of the future.For this silicone heart to be workable as a heart replacement, it needs to last longer and a second prototype is under development, according to Kohll. Both Kohll and Cohrs are doctoral students of study lead Wendelin Stark, PhD, professor at the Institute for Chemical and Bioengineering of ETHZ and head of Functional Materials Engineering.

"We are motivated about this second prototype and so far the results are very promising," Kohll said.

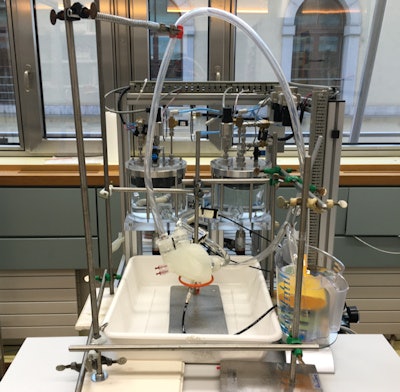

Anastasios Petrou, mechanical engineer at ETHZ's Product Development Group Zurich, which tested the heart's function, explained how the silicone heart was placed in a mock circulation machine that mimics a cardiovascular system.

"We were able to use different physiological loadings to mimic exercise and other activities, to see how flow would change. We proved that the silicone heart moves and works in a similar way to a real human heart," Petrou said.