Researchers in Spain said they are using 3D-printing technology to create human skin, according to an article in Biofabrication.

One of the first-created, human living organs to reach the marketplace, the product replicates the natural structure of real human skin with an external layer, an epidermis with its stratum corneum to protect against the external environment, and a third, thicker dermis layer consisting of fibroblasts that produce collagen, the protein that gives real skin its elasticity and mechanical strength.

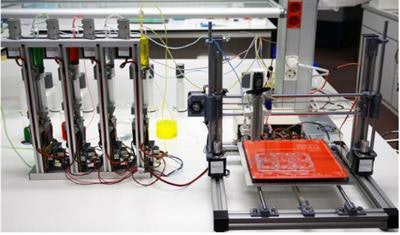

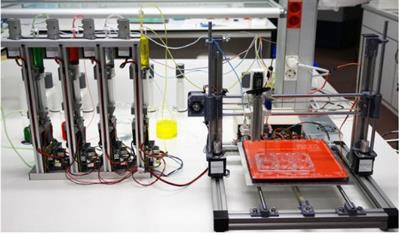

Prototype for a 3D bioprinter that creates functional human skin. Image courtesy of UC3M.

Prototype for a 3D bioprinter that creates functional human skin. Image courtesy of UC3M.The skin "can be transplanted to patients or used in business settings to test chemical products, cosmetics, or pharmaceutical products in quantities and with timetables and prices that are compatible with these uses," said Dr. Luis Jorcano, a professor in the department of bioengineering and aerospace engineering at Madrid's Carlos III University, in a statement accompanying the release of the study (Biofabrication, 5 December 2016).

When creating skin, bioinks are used instead of cartridges and colored inks, and extruded from injectors, the authors noted. Knowing how to mix the biological components, create the necessary conditions in which to work with them to avoid deterioration, and correctly depositing the product, is critical. Deposit of the bioinks, which are patented to Ciemat and licensed by the BioDan group, are controlled by a computer that deposits them on a print bed to produce the skin, the authors wrote.

The process can be used either to create allogeneic skin from a stock of cells for industrial process, or to create autologous skin made from the patient's own cells and designed for therapeutic use, they wrote.

Only human cells and components are used to produce skin that is bioactive and can generate its own collagen, the authors noted. This kind of bioprinting allows skin to be generated in a standardized, automated way, for a lower cost than manual production. The tissues can be used to test pharmaceutical products, as well as cosmetics and consumer chemical products where regulations require testing that does not use animals.