Offering more than 100 times the image resolution of MRI and CT, micro-CT may serve as an alternative to standard imaging modalities in the production of 3D-printed models -- especially for tiny, complex structures, according to research from London's leading pediatric center.

The researchers, led by Dr. Owen Arthurs, PhD, from Great Ormond Street Hospital for Children, examined the growing use of micro-CT as the basis of 3D-printed anatomical models. They found the high resolution of 3D-printed models based on micro-CT scans helped improve the characterization of smaller structures, as well as provided new insight into various medical specialties (BJR, 31 July 2018, Vol. 91:1088, 20180306).

"We can now model smaller and more complex anatomical structures that were previously beyond the limits of conventional medical scanning parameters," Arthurs and colleagues wrote. "This in turn will expand our ability to understand structures that were once beyond the limits of our imaging technology."

Higher image resolution

Clinicians most frequently use data from CT and MRI to create 3D-printed anatomical models. However, the resolution of conventional CT and MRI scans is often not high enough to create precise 3D-printed models of very small and intricate structures.

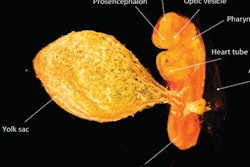

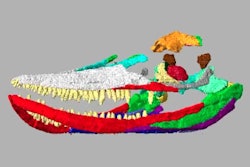

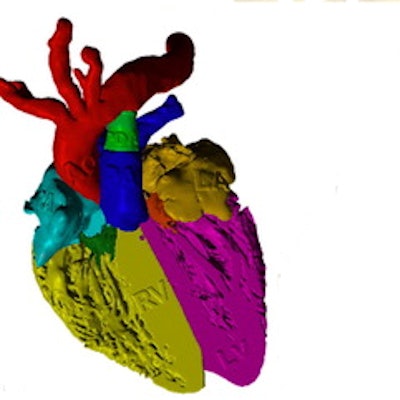

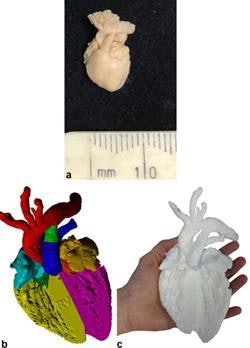

A 3D printing from micro-CT of an archival 16 week gestation fetal heart for educational purposes. (a) External appearances of the fetal heart, measuring under 1 cm in length, (b) virtual 3D volume rendered micro-CT imaged model with cardiac segments color-coded and (c) final 3D-printed model, resized to 10 x 10 x 10 original dimensions for use as an educational tool. All images courtesy of BJR.

A 3D printing from micro-CT of an archival 16 week gestation fetal heart for educational purposes. (a) External appearances of the fetal heart, measuring under 1 cm in length, (b) virtual 3D volume rendered micro-CT imaged model with cardiac segments color-coded and (c) final 3D-printed model, resized to 10 x 10 x 10 original dimensions for use as an educational tool. All images courtesy of BJR.In contrast, micro-CT scans have a considerably higher image resolution; the voxel size of micro-CT scans is less than 0.001 mm, compared with 0.7 mm for typical CT and MRI scans, according to the authors. This dramatically lower voxel size can enhance the visualization of small structures -- such as bone trabeculations and placental vasculature -- and can ultimately make way for the production of more accurate 3D-printed models.

Yet there are several drawbacks of using micro-CT for 3D printing, including a smaller field-of-view, higher radiation dose, and longer scanning time (between 10 minutes to several hours) than standard CT. Furthermore, imaging tissues of similar densities typically requires the administration of a contrast agent. As a result of these and other limitations, clinicians do not use micro-CT to image organs of live individuals, but rather those of ex-vivo or postmortem bodies.

"Whilst micro-CT imaging does not currently allow for in-vivo imaging of patient anatomy, it can help in the imaging of tools to aid complex virtual reconstructions," the authors wrote. "Some of the simplest items to image with micro-CT and, potentially print, are those with inherent high contrast to noise, i.e., metallic tools such as screws, plates, and springs."

Clinical applications

Among the early clinical applications of 3D printing with micro-CT, several have shown promise in the following fields:

- Cardiac imaging. Understanding complex congenital heart defects demands a high level of expertise, and standard MRI or ultrasound scans only offer limited visualization, the authors noted. Micro-CT scans of ex-vivo fetal hearts can provide the image resolution required to create realistic 3D-printed models. The detail of these 3D-printed fetal hearts -- especially when rescaled to larger sizes -- can allow clinicians to better appreciate intricate structures such as the oval fossa at various stages of fetal development.

- Craniofacial surgery. The main applications of micro-CT in surgery are generating virtual models of surgical tools to facilitate the selection of correctly sized tools and reconstructing possible postsurgical appearances. In the future, this may lead to the development of individually tailored surgical tools and plates.

- Placental imaging. Micro-CT can capture the deep-branching vessel structure of the placenta, allowing for its quantification and conversion into a 3D model. "3D printing from micro-CT imaging data allows the complexity of placental vasculature to be appreciated .... and may open a new window into our understanding of normal pregnancy and the role of the placenta in major obstetric disorders, including fetal growth restriction, pre-eclampsia, and complicated twin pregnancies," the authors wrote.

- Postmortem fetal imaging. "Postmortem perinatal micro-CT imaging has been shown to be a highly accurate and less invasive alternative to conventional autopsy, especially for fetuses in whom conventional imaging provides insufficient resolution," they wrote. "[Three-dimensional] printing at a magnified scale can allow practical handling ... [and] can help to explain to parents what abnormalities were present."

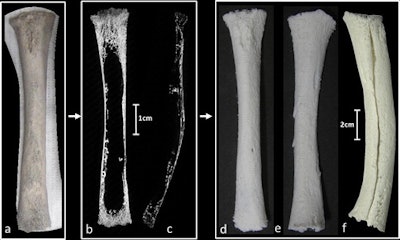

- Postmortem bone imaging. Three-dimensional-printed models of bone fragments based on conventional CT scans tend to be very fragile and usually do not provide sufficient detail of bony microstructures, the group noted. Models created from micro-CT scans, on the other hand, are robust and detailed enough to have researchers physically match different fragments and distinguish various causes of bone disease.

Continued expansion

As the field of medical 3D printing advances, clinicians may begin turning to other forms of high-resolution imaging to create anatomical models. For example, techniques such as synchrotron and lab-based radiation phase contrast imaging provide even greater detail of soft tissue microstructure than micro-CT. Nano-CT also surpasses the image quality of micro-CT, boasting an image resolution as small as 100 nanometers.

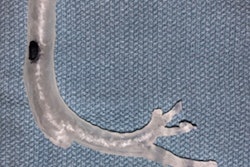

Imaging to 3D printing of a neonatal right tibia from “Parrot’s bone” collection. (a) One-half of an original bone specimen, cut by the 19th century French doctor in a longitudinal section and subsequently mounted onto polystyrene, with cut surface facing the mounted material. (b) Micro-CT image of the same specimen in both longitudinal 2.5 mm thick slab view and (c) nonmanipulated micro-CT sagittal plane. The bone was extremely porous and also bowed in the sagittal section making handling particularly challenging. (d) A 3D-printed version of the bone specimen twice life size and (e) the subsequently matched longitudinal “half section” within the collection. This was only possible by 3D printing the entire collection and physically matching the components together by trabecular pattern, size and pathology as shown in (f).

Imaging to 3D printing of a neonatal right tibia from “Parrot’s bone” collection. (a) One-half of an original bone specimen, cut by the 19th century French doctor in a longitudinal section and subsequently mounted onto polystyrene, with cut surface facing the mounted material. (b) Micro-CT image of the same specimen in both longitudinal 2.5 mm thick slab view and (c) nonmanipulated micro-CT sagittal plane. The bone was extremely porous and also bowed in the sagittal section making handling particularly challenging. (d) A 3D-printed version of the bone specimen twice life size and (e) the subsequently matched longitudinal “half section” within the collection. This was only possible by 3D printing the entire collection and physically matching the components together by trabecular pattern, size and pathology as shown in (f).These alternative high-resolution imaging modalities, however, are much more costly than micro-CT and are primarily reserved for imaging objects and insects.

"The applications of micro-CT and 3D printing for research, education, training, surgical planning, and novel prostheses are fast expanding," the authors wrote. "The increased availability of 3D printers and the variety of printing materials will aid future developments and will lead to more rapid and simplified software segmentation and more advanced computational analyses."