Researchers from Germany and the U.S. have created 3D-printed models based on dual-energy CT (DECT) scans, which improved the efficiency of image segmentation within the 3D printing workflow compared with using conventional CT, according to an article recently published online in 3D Printing in Medicine.

The group explored the potential of DECT to enhance the 3D visualization of intricate anatomy for the management of four cases from different clinical specialties. Using the technology resulted in easier and faster image segmentation when processing patient-specific 3D-printed models, the researchers found (3D Print Med, 18 January 2019).

Ultimately, incorporating DECT into the medical 3D printing workflow could eventually lead to more advanced clinical imaging applications, according to co-lead authors Dr. Elias Kikano from Case Western Reserve University in Cleveland, Ohio, U.S., and Dr. Nils Große Hokamp from University Hospital Cologne.

"The utilization of [dual-energy] CT for medical 3D printing may improve segmentation of target anatomy and even salvage certain cases without any change in protocol," Kikano told AuntMinnieEurope.com.

New role for DECT

The realistic and tactile nature of 3D-printed models has encouraged clinicians to use them for presurgical planning and intraoperative guidance, with numerous studies confirming that the models enhance visualization and help lower surgery times, among other benefits.

One of the main barriers to more widespread integration of 3D printing into healthcare has been the extensive amount of time it takes to process the medical images on which the models are based, the authors noted. Among the processing steps, manual image segmentation is often the most time-consuming and rigorous -- particularly so when dealing with images involving artifacts and low attenuation.

To bolster the processing of images for 3D printing, Kikano, Große Hokamp, and colleagues turned to spectral CT, a type of DECT technology that does not require protocol selection prior to scanning. They believed that combining conventional CT with virtual monoenergetic images derived from spectral CT scans could facilitate segmentation by providing higher-quality images.

"There is a growing availability of dual-energy CT throughout academic centers and major hospitals," Große Hokamp said. "The most abundant applications are related to an increase of soft-tissue and contrast-media-related contrast. A strong emphasis is also placed on abdominal and oncologic applications to improve lesion conspicuity and characterization ... [and] reduce metal artifacts."

The researchers collected the conventional CT scans of four complex cases and subsequently obtained virtual monoenergetic images of the patients' DECT scans. Next, they performed image segmentation of the conventional CT scans and virtual monoenergetic images using software tools built into the CT scanner image viewer (IntelliSpace Portal 9.0, Philips Healthcare). After converting the images into 3D virtual models, they finally created a patient-specific 3D-printed model for each case using a desktop 3D printer (Form 2, Formlabs).

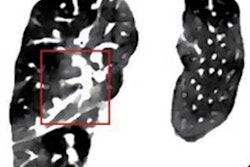

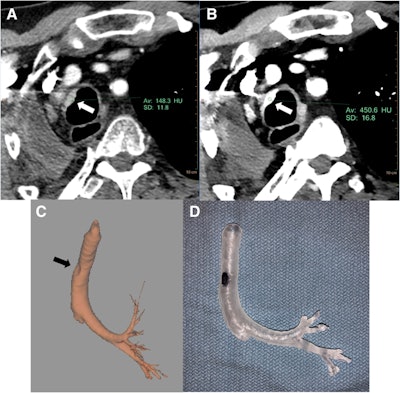

Conventional CT scan (A), DECT scan (B), 3D volume-rendered DECT scan (C), and 3D-printed model of the bronchial tree (D). The virtual monoenergetic image of the DECT scan enhances visualization of the tracheal malignancy (white arrow). Image courtesy of Kikano et al. Shared via Creative Commons license.

Conventional CT scan (A), DECT scan (B), 3D volume-rendered DECT scan (C), and 3D-printed model of the bronchial tree (D). The virtual monoenergetic image of the DECT scan enhances visualization of the tracheal malignancy (white arrow). Image courtesy of Kikano et al. Shared via Creative Commons license.Using virtual monoenergetic images of the DECT scans in place of conventional CT offered several advantages, including the following:

- More than doubling the attenuation of vasculature and other key structures

- Decreasing segmentation time

- Enhancing fracture visualization

- Reducing metal artifacts by as much as 90%

Faster, easier segmentation

Overall, using DECT made the 3D printing segmentation process "faster" and "easier," as well as increased the operator's confidence during segmentation, the authors noted. These benefits allowed for the generation of more accurate 3D volume-rendered models and, in turn, more realistic 3D-printed models. In addition, the DECT data allowed the clinicians to create precise 3D-printed models in two cases for which using conventional CT yielded inaccurate 3D-printed models.

"Two of the cases would not have been possible to segment at all without using virtual monoenergetic imaging data," Kikano said. "The best part is that the virtual monoenergetic data in spectral CT is acquired for free (no extra scan or radiation), so it's always available as an option when segmenting."

Furthermore, the researchers were able to use the 3D-printed models produced based on DECT scans to assist resident education, patient consultation, and preoperative planning. Nonetheless, they acknowledged that there were several limitations to adding DECT to the 3D printing workflow.

"Some of the current disadvantages of relying on virtual monoenergetic images include accessibility to the spectral-detector CT scanner, prospectively protocoling on nondetector-based dual-energy scanners, and limited native software compatibility," Kikano said.

"Virtual monoenergetic images can also result in blooming of strongly attenuated structures ... although simple precautionary steps can be taken to avoid most of these issues," Große Hokamp added.

In the near future, the group plans to determine more concretely the amount of time that using DECT can save for image segmentation and, ultimately, in producing 3D-printed anatomical models.