Facial reconstructive surgery appears to have turned a corner, judging by a recent case in the U.K. that would have challenged even the most experienced and skilled surgeon. A patient's face was rebuilt after a horrific motorbike accident, and 3D visualization techniques made an essential contribution to the successful outcome.

In February 2014, Adrian Sugar, a consultant maxillofacial surgeon based at Morriston Hospital in Swansea, carried out an extensive facial rebuild on Stephen Power that had been months in the planning. Scans of the patient's skull, combined with precisely engineered 3D imaging and printing of guides and titanium implants, were key to the success of the work.

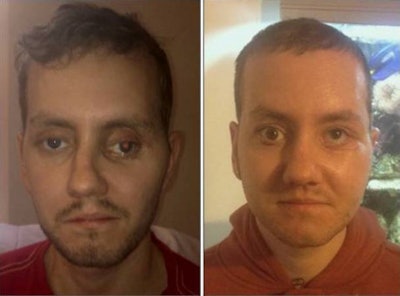

Stephen Power pictured before and after 3D facial surgery. All images courtesy of Adrian Sugar.

Stephen Power pictured before and after 3D facial surgery. All images courtesy of Adrian Sugar.Reconstructive surgery of a shattered face usually requires a certain degree of guesswork, but with 3D printing, much greater precision is introduced into the procedure. The reconstructive work on Power's face was also conducted many months after the injuries were sustained and initial surgery had already been conducted, taking the complexity and technical skill required to a new level.

Sugar told AuntMinnieEurope.com how the planning process was long and intricate, and how 3D came into effect for the production of guides used during the operation and the titanium plates that now sit inside Power's face. The plates provide the structure and strength to hold together the bone shattered in the accident.

Plastic guides were made via 3D printing in chrome cobalt, and they were used as a means of ensuring that the extensive plans and models drawn up with the aid of computer simulations and physical models can be precisely translated across to the operating table.

Essentially, 3D printing is an extension of the 2D paper printing used by most people every day. There are just more successive thinly sliced layers to the process. The information originates from a digital 3D image file designed on 3D modeling software, and this is sent to a printer that creates the 3D object for real.

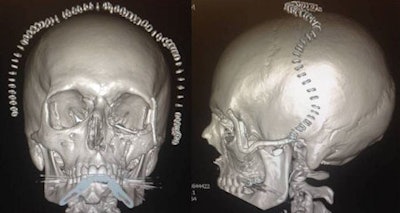

X-rays of Stephen Power's skull.

X-rays of Stephen Power's skull.Of all the explanations of 3D printing, probably the best involves imagining a multilayer loaf of bread: Each thin slice is laid down one at a time until the entire loaf is formed to make a 3D object whether loaf of bread, manufacturing component, or facial feature. With facial surgery, the principle is the same if more complex than bread making.

Similar to a 2D paper printer that uses a file designed on a program like Word, a 3D printer also requires instruction that it sources from a computer-aided design (CAD) file. This is created using a 3D modeling software program that is relayed to the 3D printer. Either way, the program creates a file that is sent to the 3D printer. The 3D printer software slices the design into hundreds of horizontal layers, and these are then printed layer by layer on top of each other to create the 3D object.

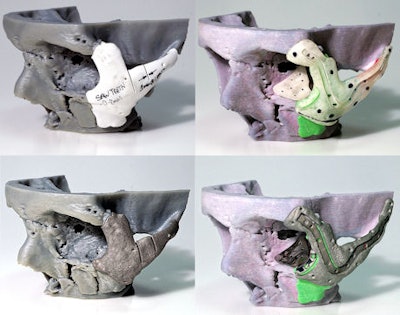

In Power's case, 3D imaging was used to create a 3D virtual model on a computer screen and to mirror image the normal onto the abnormal side of the face. The virtual model was then cut up to try to achieve that ideal symmetry. Three-dimensional printing was then used to produce physical models and simulate the surgery. Only when the ideal solution had been produced were guides then made, initially virtual guides on the screen, and then actual physical guides by 3D printing.

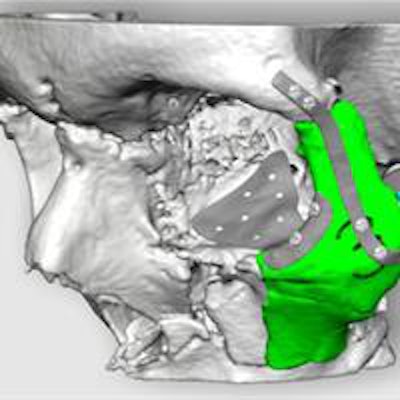

A 3D mold of the patient's face was made before the titanium implants were created.

A 3D mold of the patient's face was made before the titanium implants were created."It was what we did and how we did it," Sugar said. "A cutting guide was used to direct where to cut the bone exactly, and secondly, a guide to reposition the bone in the right place."

He emphasized that despite the lack of radiologists directly involved in the project, radiologists and radiographers produce the CT scans from which the digital data are used. CT scans both before and after Power's operation demonstrated the changes achieved. The CT scan on which the entire later reconstructive procedure was based was the postoperative CT data collected following initial surgery in 2012, soon after Power's accident, and these images were introduced into two of the advanced 3D imaging software packages.

The scan data demonstrated that the problem lay in the gross displacement of Power's left cheekbone and the orbital floor; the floor was positioned very far inferiorly. "Our aim was to restore Mr. Power's normal symmetry and position of the left orbital rim and walls, and by doing so, place the globe of the eye into a normal position vertically, horizontally, and in projection. We also wanted his vision to be good and his eye movements to be normal."

Prior to the real surgery, detailed planning of each stage of the operation was performed digitally. The first 3D virtual model created included all the plates and screws placed at Power's initial surgery straight after the accident. Those plates and screws had first to be digitally removed from the 3D image, then the right side of the face had to be mirror imaged for symmetry and positioning.

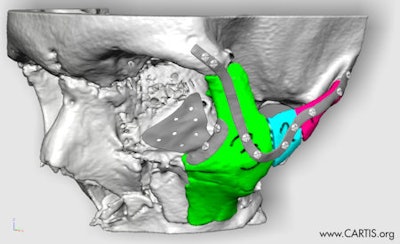

Power's skull and cheekbones were repositioned using plate designs. The project is the work of the Centre of Applied Reconstructive Technologies in Surgery (Cartis).

Power's skull and cheekbones were repositioned using plate designs. The project is the work of the Centre of Applied Reconstructive Technologies in Surgery (Cartis)."The mirror image meant we had a good idea of what we were aiming for," Sugar said. "One of the 3D software packages allows us to cut, move, create, and build structures on the screen using a 3D mouse with digital biofeedback so we can feel what we are doing. Because the right cheekbone was in a relatively good place, it was used as a norm allowing us to do mirror imaging from that position."

However, Power's initial injuries included multiple fractures of the midface at Le Fort III level (left and right cheekbones, orbital floor, nose, and naso-orbito-ethmoid complex and maxilla), as well as complex fractures with skin loss of his lower right leg and both arms. The whole process was not without its challenges.

The surgery on Power broke some new ground in terms of the use of 3D printing at every stage of his quite complex reconstruction. "It's nice if you can just refracture a bone and move it, but even if this can be done in one piece, doing it late means you cannot fix the pieces back together like a jigsaw -- new bone has grown so new callus formation has to be carefully removed to allow the pieces to fit together properly," Sugar said.

The decision about what bone, how much, and from where to remove it is and was challenging and "can be almost guesswork," he noted.

"Even in our case, as identified on six or seven images, three areas had been removed on models, but still, replicating this in theater is challenging because it is difficult to know how much bone to actually remove," he added.

Asked whether he believed 3D printing was the future of reconstructive surgery, Sugar said that he expected the technique to be used more commonly.

The work of the team at Morriston Hospital was conducted in close collaboration with the Centre for Applied Reconstructive Technologies in Surgery (Cartis). Cartis is a collaboration between the team in Swansea and scientists at Cardiff Metropolitan University. An exhibition at the Science Museum in London is currently featuring Power's case in the "3D: Printing the Future" exhibit.