Researchers in Austria are using CT to create perfect copies of patients' shoulder joints to replace their own worn-out parts. The translational research project shows how 3D models and special mathematical methods can be used to improve the design and integration of implants in the body on an individual-patient basis, they said.

Dr. Karl Entacher from Salzburg University of Applied Sciences, and Peter Schuller-Götzburg from the Paracelsus Medical University, in Salzburg, Austria, built human joint CT models based on CT and MRI images and then used them to simulate various load conditions in the model.

"Modern tomography techniques allow us to create images of an entire shoulder joint layer-by-layer, and the layer thicknesses that we can achieve today make excellent resolution possible," noted Entacher. "We were able to use this image data to create computer-generated 3D models of each patient´s individual shoulder joint, forming the basis for our subsequent analysis."

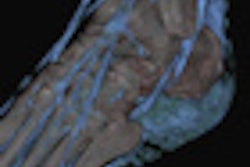

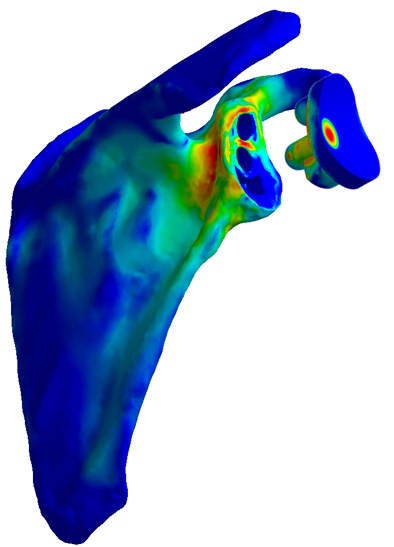

Fit by numbers -- 3D models allow for individually optimized implants. Image courtesy of Dr. Karl Entacher.

Fit by numbers -- 3D models allow for individually optimized implants. Image courtesy of Dr. Karl Entacher.To date the implants have been created and implanted in five patients using two different types of implants -- based on either keeled or pegged glenoid components, Entacher explained in an email to AuntMinnieEurope.com.

Image data were collected from CT and MRI data, which were used to generate 3D models specifically for shoulder joints and their replacements. The data were analyzed by a process known as the finite element method.

This method permits objects to be analyzed and digitized using small but finite elements. Their movement can then be tracked digitally and simulated based on variables such as material properties, load, and the limits of movement, thereby modeling all of the conditions to which a joint might be subjected in the human body, according to Entacher.

"We were able to use this image data to create computer-generated 3D models of each patient's individual shoulder joint, forming the basis for our subsequent analysis," he said. "The models are generated from one CT scan and the movements and implant loadings are carried out virtually."

"We are currently analyzing our possibilities of forecasts for the patients after our analyses," Entacher told AuntMinnieEurope.com. "The goal for the following three years is development of a special implant for a shoulder implant revision which will also be tested in clinical studies. Therefore we will use our know-how for patient specific analysis and simulation."

For now, the specific materials and methods of creating them must remain under wraps as the next phase of the project is still in draft proposal form.

The 2012 translational research program was funded by the Austrian Science Fund (FWF) and conducted on behalf of the country's Federal Ministry for Transport, Innovation, and Technology.